Laser cutting

Laser cutting is powerful and precise. We use modern systems to cut sheet metal up to large formats (1500 x 3000 mm) and up to 20 mm material thickness. Laser cutting allows complex geometries and shapes to be cut.

Laser cutting is powerful and precise. We use modern systems to cut sheet metal up to large formats (1500 x 3000 mm) and up to 20 mm material thickness. Laser cutting allows complex geometries and shapes to be cut.

With up to 600 tons of pressing force, we can shape materials into the desired form on seven systems. Forming opens up a wide range of possibilities for designing components and achieving specific properties, which ensures efficient production and higher quality.

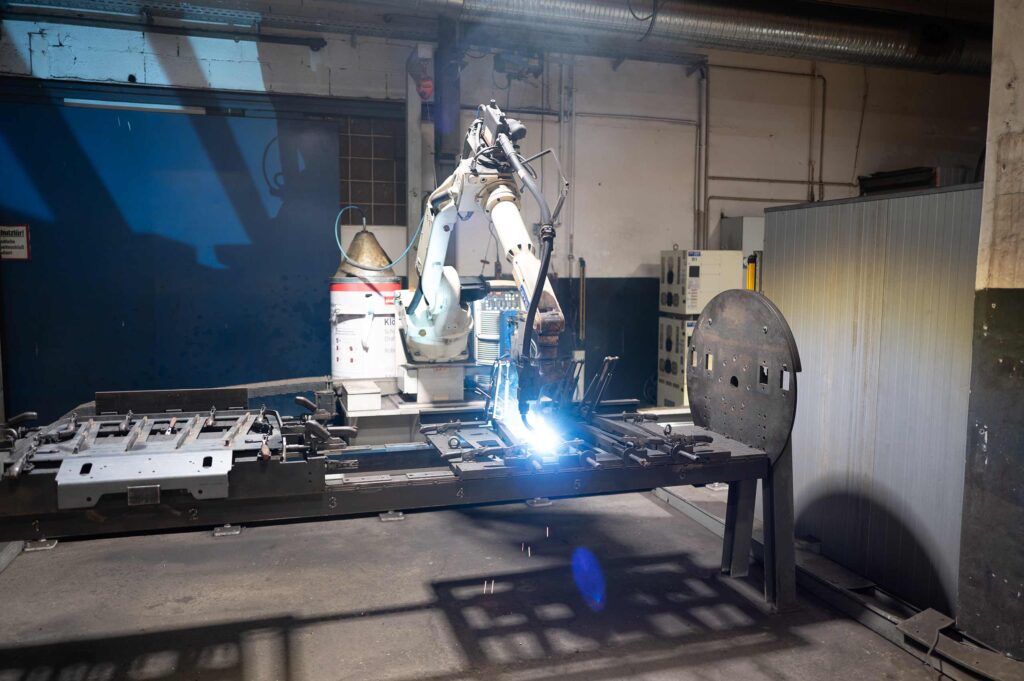

Welding offers numerous advantages in industrial production. We rely on precise manual work and automated 6- to 15-axis welding robots to join sheet metal. This method can be used to produce components with a unit weight of up to 500 kg and dimensions of 3,300 x 1,400 x 700 mm.

The mechanical processing on our four 4-axis machining centers enables high precision and quality of the manufactured parts and thus offers an efficient and cost-effective solution for ready-to-install products.

The maximum processing size is 2,240 x 810 x 750 mm and the maximum weight is 1,000 kg.

In final assembly, individual components are joined together to form highly complex assemblies. As a partner in final assembly, maweco offers its customers the advantage of receiving ready-to-install parts that can be used directly without further time-consuming and costly work steps. Not only mechanical but also electrical function tests are carried out to ensure that the end product meets the highest quality standards.

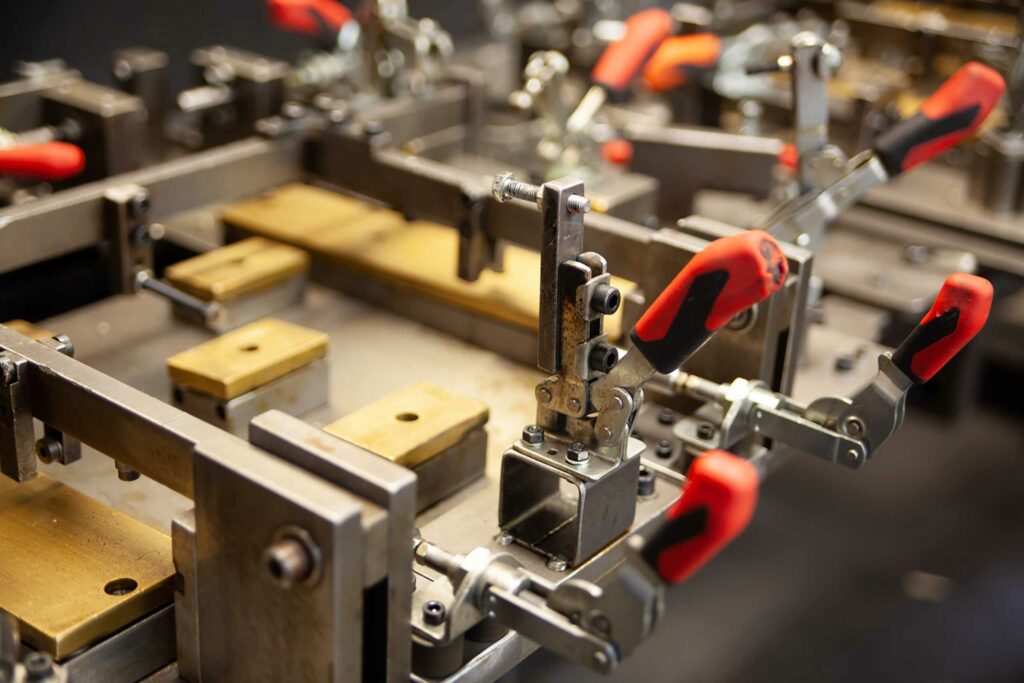

Fixture construction is an important component in our production process. Our internally developed, manufactured and tested devices enable us to produce economically and to a consistently high quality. By using devices, we can automate and standardize work processes, which leads to greater efficiency and reproducibility. This saves us time and money and enables us to offer our customers a high-quality product at a competitive price.

Our products can be prepared in our throughfeed blasting system (maximum processing size 2,500 x 1,000 x 450 mm, maximum weight 250 kg) to meet the highest requirements for subsequent preservation and painting. The parts are given the finishing touches at one of our hand sanding workstations.

Our certified partner companies offer individual coatings and treatments to meet our customers’ requirements. The surface treatment makes the manufactured parts more resistant and durable, thus improving their quality and performance.

Fixture construction is an important component in our production process. Our internally developed, manufactured and tested devices enable us to produce economically and to a consistently high quality. By using devices, we can automate and standardize work processes, which leads to greater efficiency and reproducibility. This saves us time and money and enables us to offer our customers a high-quality product at a competitive price.

The quality of our products, services and processes is the focus of all maweco’s activities. Modern measuring and testing technology is standard for us. In addition to a portable measuring system (Faro arm), we use spectral analysis and the magnetic pulse method. Macrosection and hardness tests are the other tests we carry out.

We are certified according to IATV 16949:2016.

We also meet the standards for a specialist welding company:

maweco GmbH & Co KG

Breite Wiese 42

57392 Schmallenberg

Tel: +49 2972 9708-0

Fax: +49 2972 9708-57

Mail: info@maweco.de